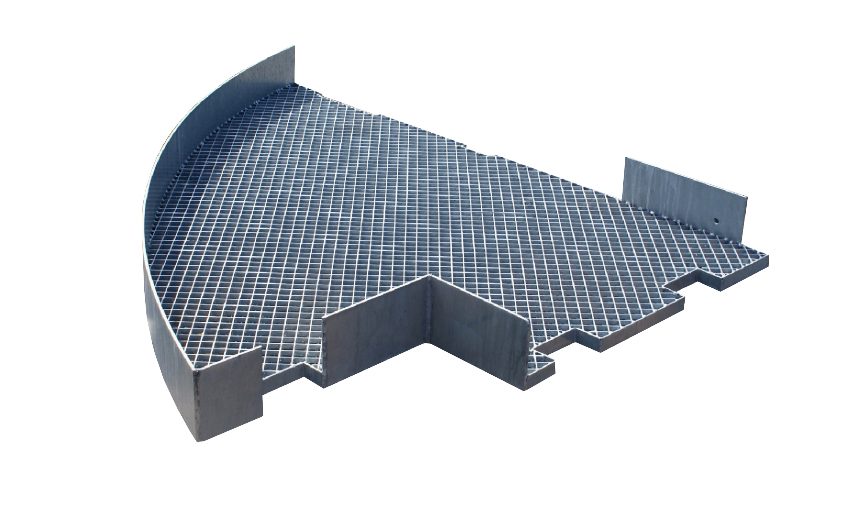

We manufacture custom-made railings, in rectangular or shapeless formats, with holes, baseboards, trapdoors, hinges and other accessories, according to each client’s project. This type of service is available for all types of railings we produce.

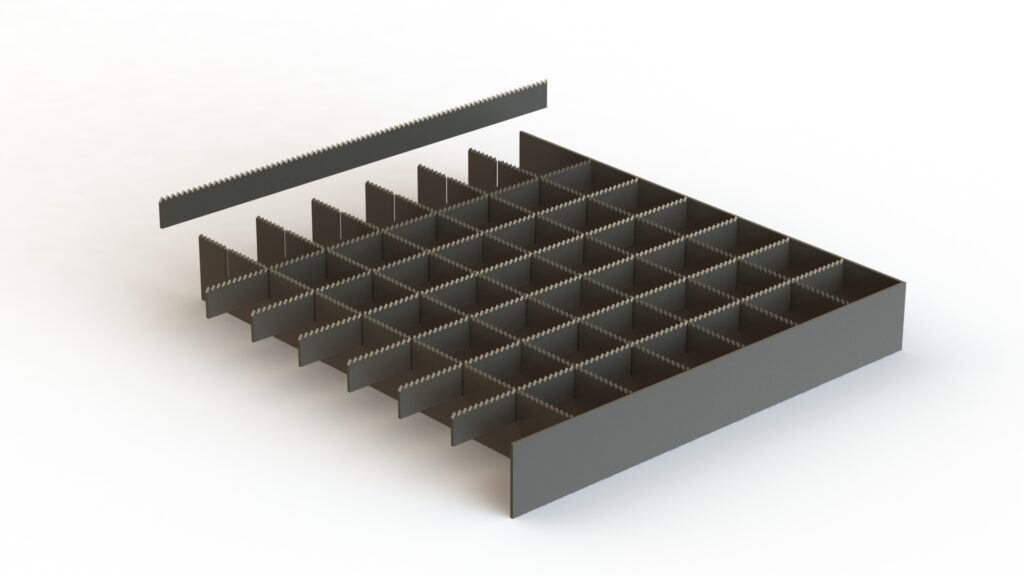

We are able to manufacture a fence with a lower safety mesh for filtering all types of pieces equal to or greater than 8.0 mm. For this we use a perforated band with square holes of 8×8 mm.

We manufacture a grating with a lower filtering mesh for all types of parts equal to or greater than 8.0 mm. The filter mesh promotes the same type of filtration as the safety mesh with a lower manufacturing cost. The safety mesh, however, allows a greater capacity to retain heavy parts that accidentally fall onto the railing, and the filter mesh, being much thinner, is more suitable for retaining smaller and lighter parts.

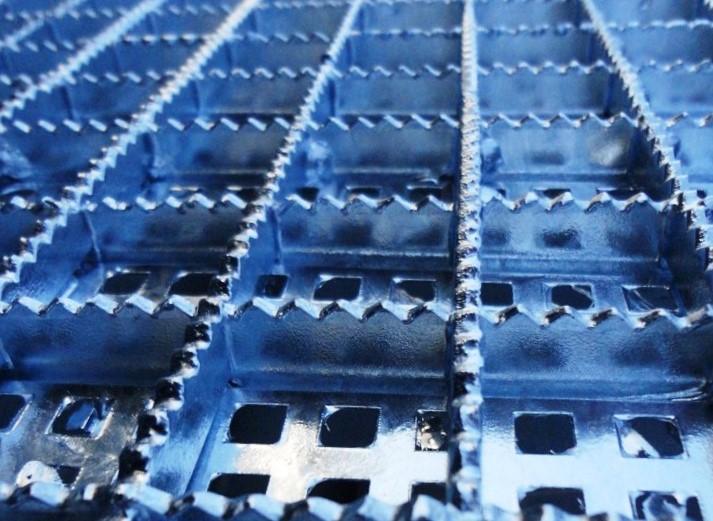

The serrated grating differs from the others due to the serrated surface of its bars. This serration is intended to intensify the anti-slip effect.

This type of finish can be applied to bar x bar railings and bar x bar rails.

This is a type of grating often used on technical floors subject to spillage of oil or other slippery substances or even just water.

The serrated effect of the bars makes it possible to intensify the adhesion of the floor to the soles of work shoes.

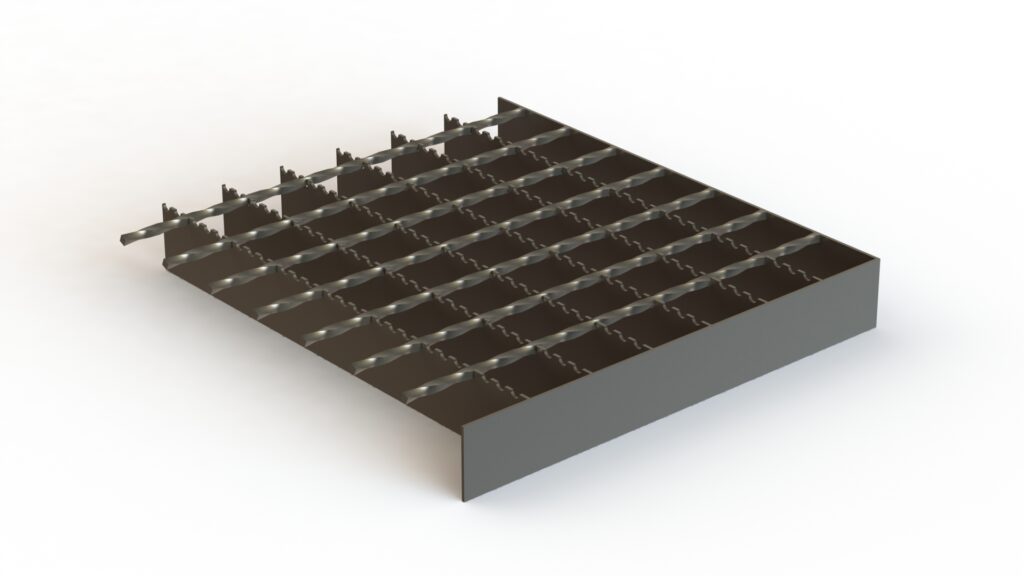

The serrated railing differs from the others due to the serrated surface of its bars. This serration is intended to intensify the ante-sliding effect.

This type of finish can be applied to bar x bar railings and bar x bar rails.

This is a type of grating often used on technical floors subject to spillage of oil or other slippery substances or even just water.

The serrated effect of the bars allows to intensify the adhesion of the floor to the soles of the work shoes.